Certified Heat Treated Pallets

In today’s global economy, there are many regulations that impact trade. In recent years, increased regulations involving wood packaging materials have been enacted to preserve forest health worldwide.

The International Standards for Phytosanitary Measures (ISPMs) are the environmental safety regulations created by the International Plant Protection Convention (IPPC). ISPM 15 is specifically for wood packaging materials, and Guidelines for Regulating Wood Packaging Material in International Trade are the world standard. This standard requires wood packaging materials consisting of solid wood components be certified as heated treated or fumigated in order to assure quarantined pests are not transported within the certified product.

There are two programs developed as quality control programs for the American Lumber Standard Committee to implement: the Heat Treatment Program and Methyl Bromide Fumigation Program. When using the Heat Treatment Program, wood products must reach an internal temperature of 56 degrees Celsius for 30 minutes or more. The Methyl Bromide Fumigation Program, although accepted by the IPSM-15 guideline, is not as popularly used given that it is not as effective nor environmentally friendly compared to the Heat Program.

Our Heat Treatment Process

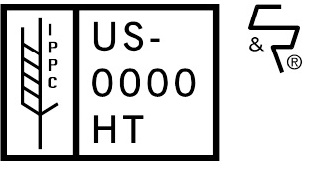

BC Wood Products (BCWP) only uses heat treatment to guarantee our wood products are pest free. During our heat treatment process, all of our wood products are put into a kiln where they are left for four to five hours to be fully treated. All heat treated wood products are then stamped with the “wheat stamp” to indicate they have been heat treated. Pictured above is an example of the “wheat stamp” that is stamped onto our wood products, which includes the wheat symbol, country of origin (US), facility code (000), and the type of treatment (HT for Heat Treatment).

Conway & Robison conducts monthly audits of our HT process to verify our compliance with this international standard. We pride ourselves on our efforts to maintain a sustainable wood pallet business model. Not only does Conway & Robinson audit our HT process to confirm we are following the guidelines, we also hold ourselves accountable to do our part to protect and preserve the environment.